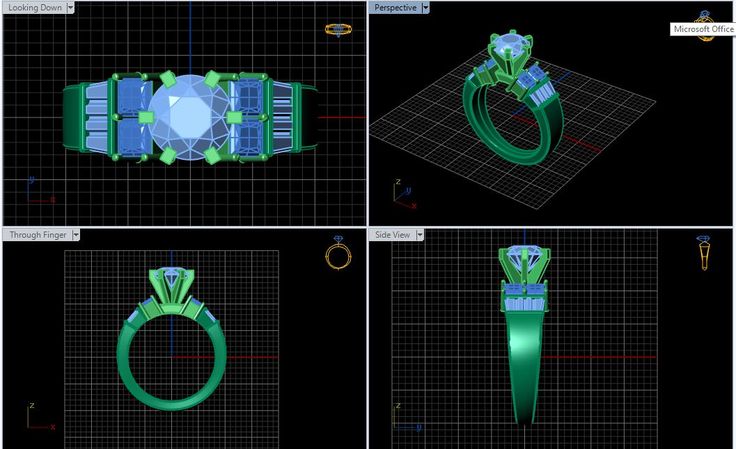

Of the two ways we proceed with custom making jewelry the first is CAD (computer aided design). This is where we have a CAD programmer using the most sophisticated programs available, design your ring on a computer. We then email you computer generated images of what your ring will look and once the customer approves, we proceed to print the wax model that will be used for casting. Once cast, our staff of professional setters and finishers turn the ring into a finished piece of one of a kind jewelry that you will be proud to wear.

The second way of producing jewelry is to hand carve the wax model and bypass the CAD process. Sometimes this actually works better. This is especially true if we are creating a custom fitted wedding band and looking for that perfect "puzzle fit." Once the wax is approved, the rest of the process is similiar to the CAD procedure and will go for casting and given to the professional setters and finishers.